TM Classic Cars: Classic car workshop & innovative laser technology

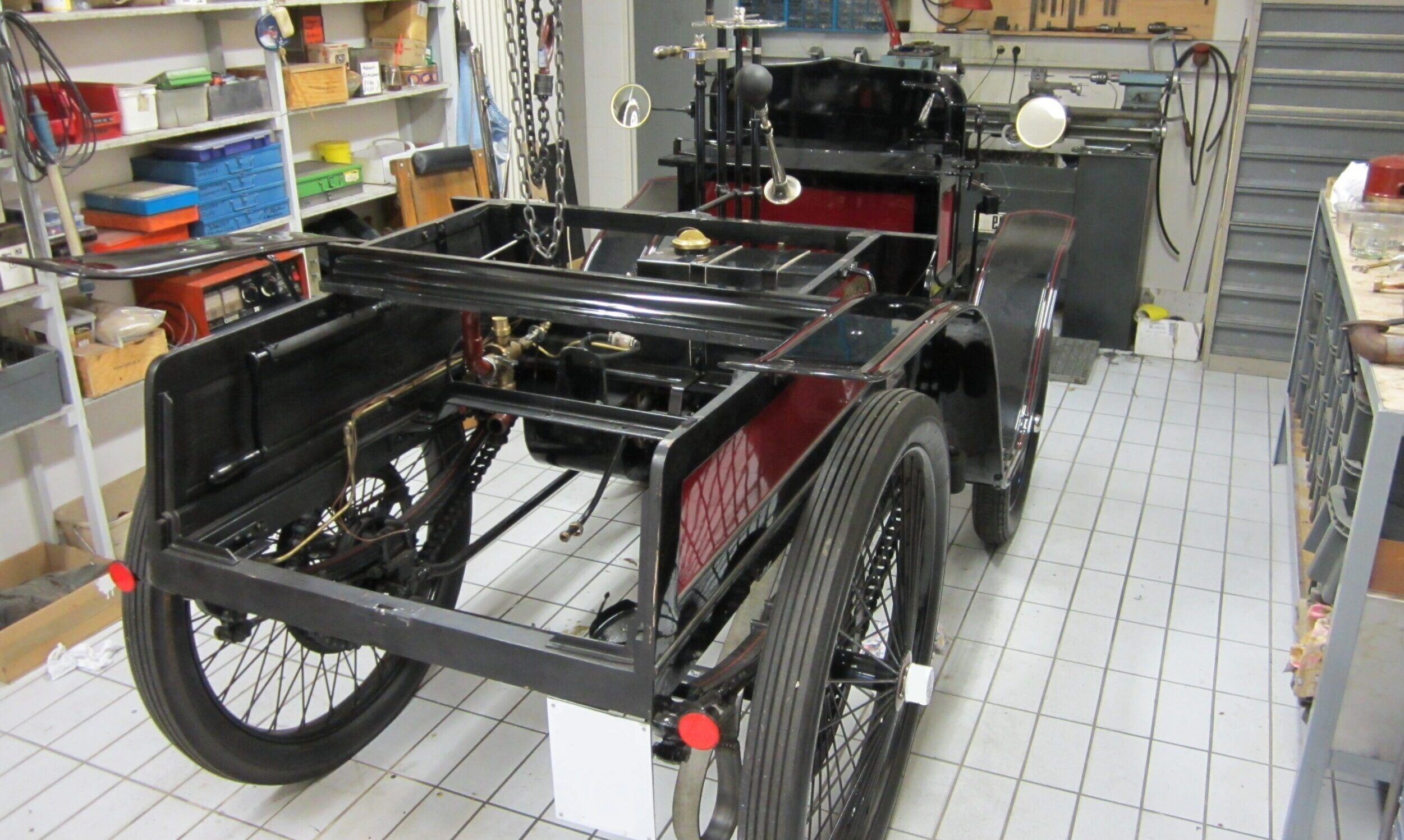

In our classic car workshop, we specialise in the repair of historic engines. Whether cylinder head repair, engine block welding, camshaft or crankshaft repair – your classic car is in the best hands with us.

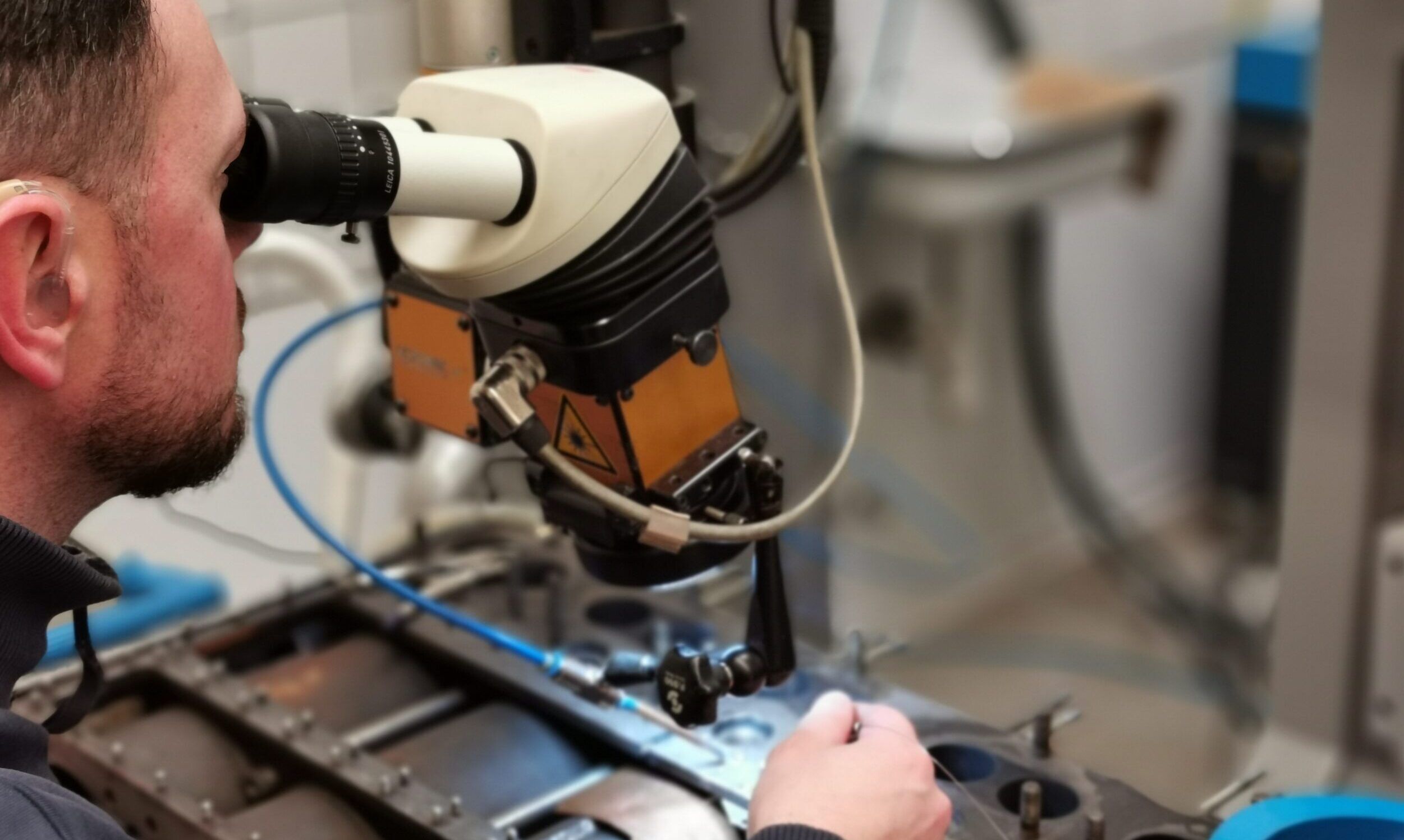

We combine old knowledge with innovative laser technology and robot-assisted as well as partially and fully automated welding processes. This gives us the possibility to produce the finest seams completely contactless, precisely and without distortion.

Gently, professionally and with great attention to detail.

Put your trust in 30 years of experience and extensive expertise.

Then we will restore your classic car to what it is:

Awareness of life, passion and driving pleasure.

At TM Classic Cars, we are intensively concerned with the level of knowledge and the skills of the experts of the time in order to preserve classic vehicles true to the original with the most modern means of today.

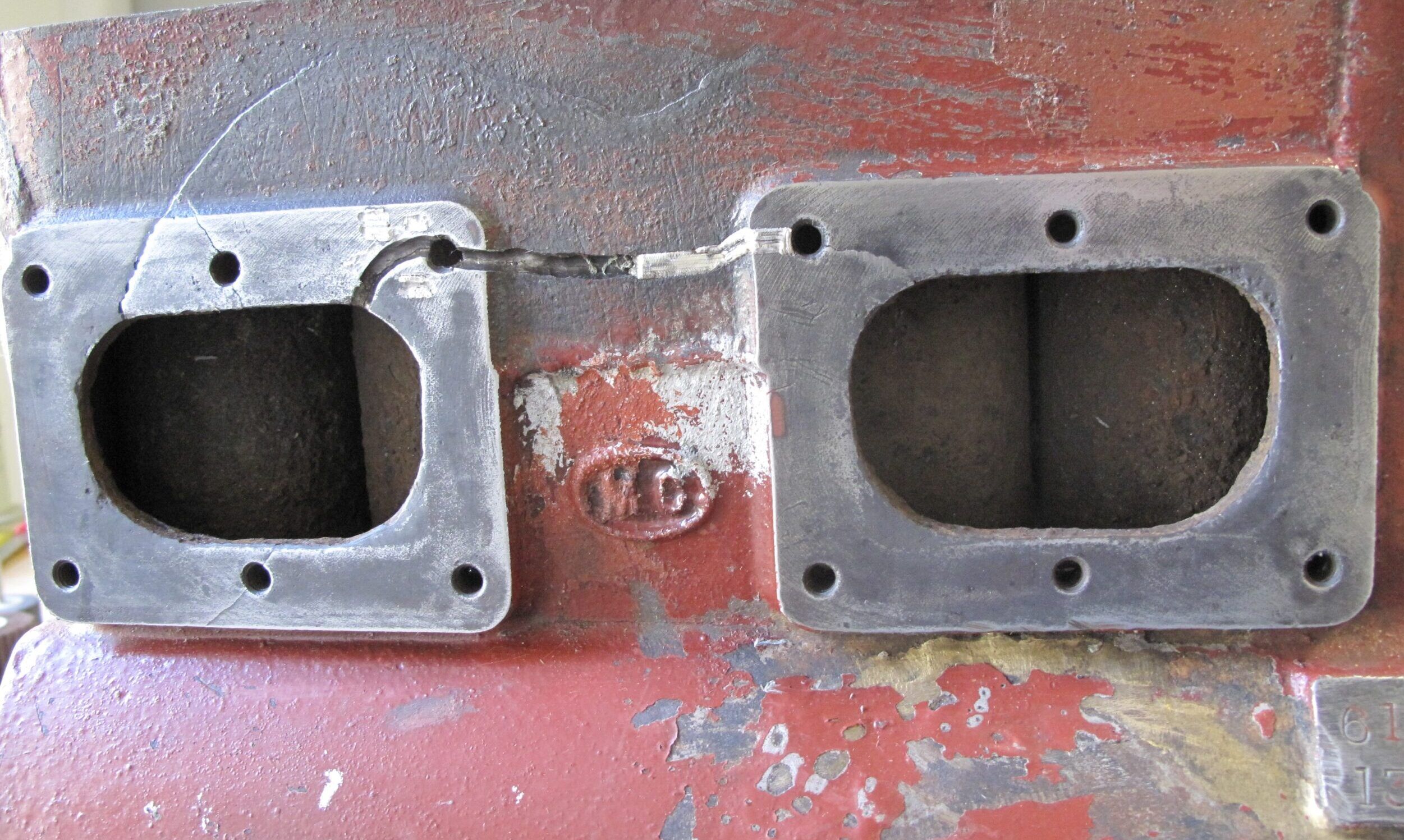

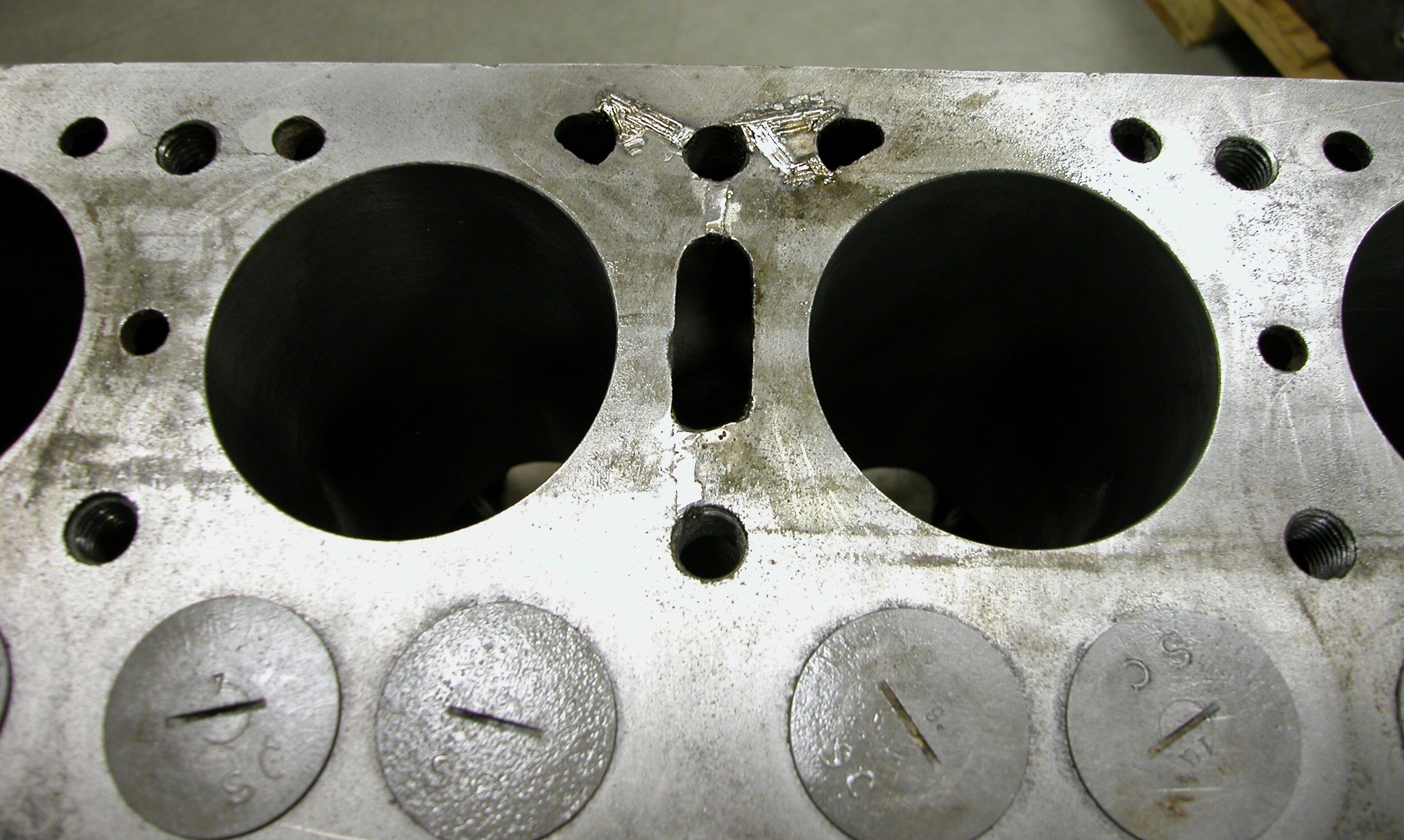

It is the enthusiasm and passion for the historic manufacturing processes and the possibilities of the most innovative technology that enable our classic car workshop to weld parts that were thought to be beyond repair, such as grey cast iron cylinder heads or aluminium engines through to magnesium gearbox housings.

Nostalgia and attention to detail make our work something very special.

What distinguishes our classic car workshop:

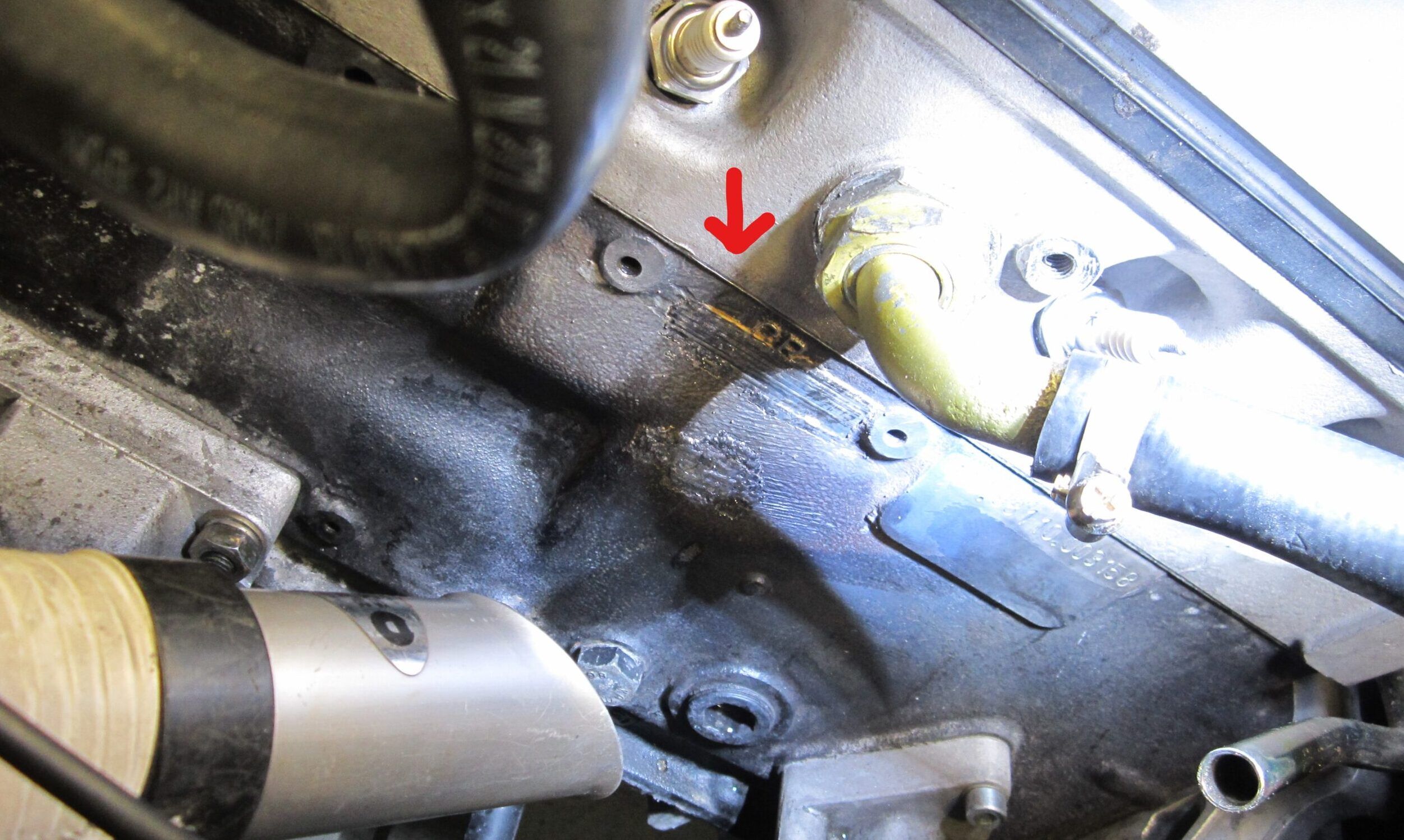

Welding cast iron

Welding cast iron / grey cast iron is considered a parade discipline of welding.

Depending on the form of the cast material (globular or lamellar), cast iron is even considered “non-weldable” in technical literature.

For more than 20 years, we have successfully implemented the findings from our constant research work in modern, laser-based welding processes. The processes are manual, partially or fully automated. Welding is high-precision, spot-welding and contactless. There is no heat distortion.

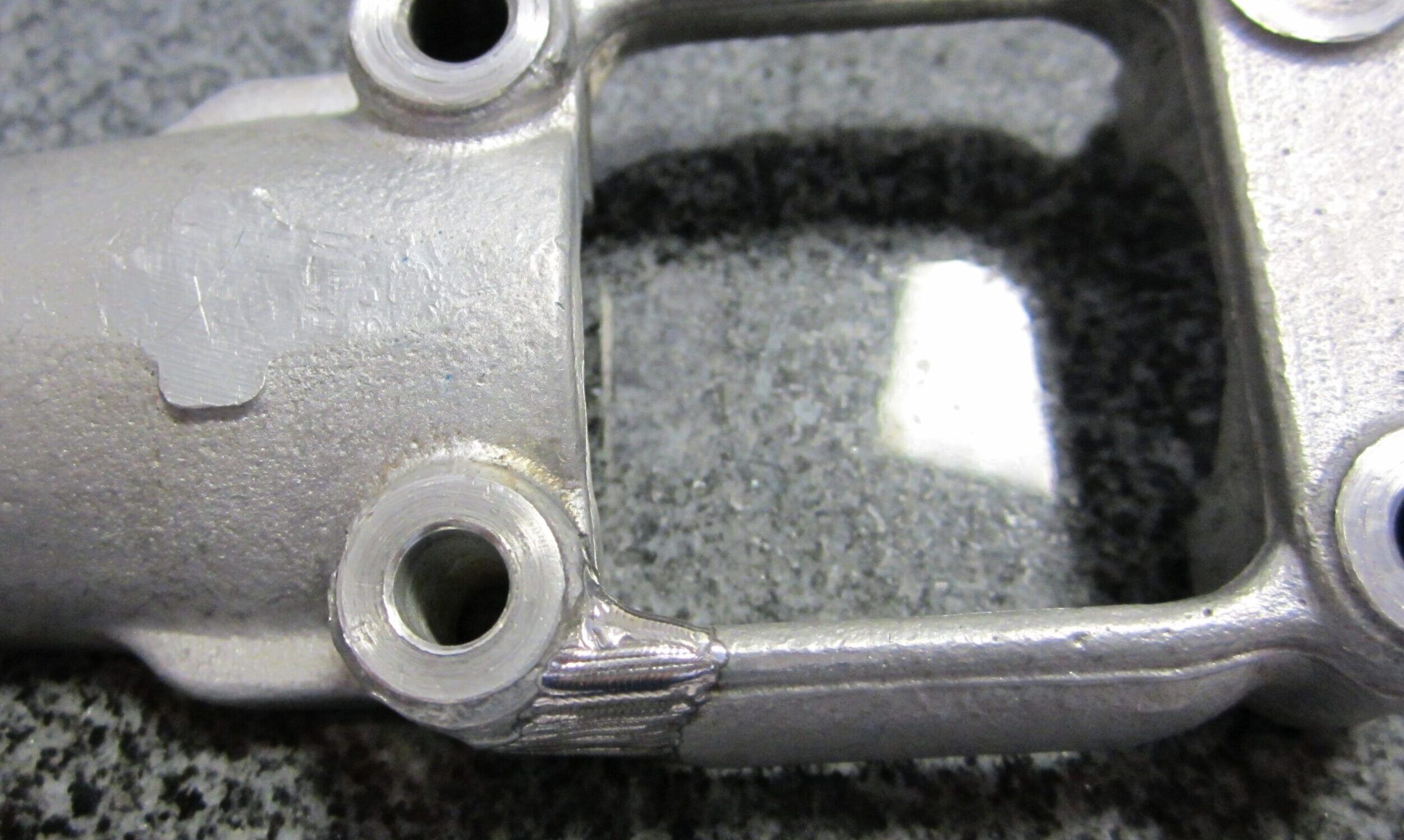

Aluminium welding

Aluminium welding requires a great deal of expertise, experience and intuition.

Aluminium alloys in particular are difficult to work with successfully in terms of quality and are also considered “non-weldable”.

Aluminium has different melting temperatures due to its oxide layer. The border between loss of stability and a weldable melt is very narrow. The aluminium is in danger of literally melting if the welding parameters are set incorrectly.

Maintaining this balance is our know-how.

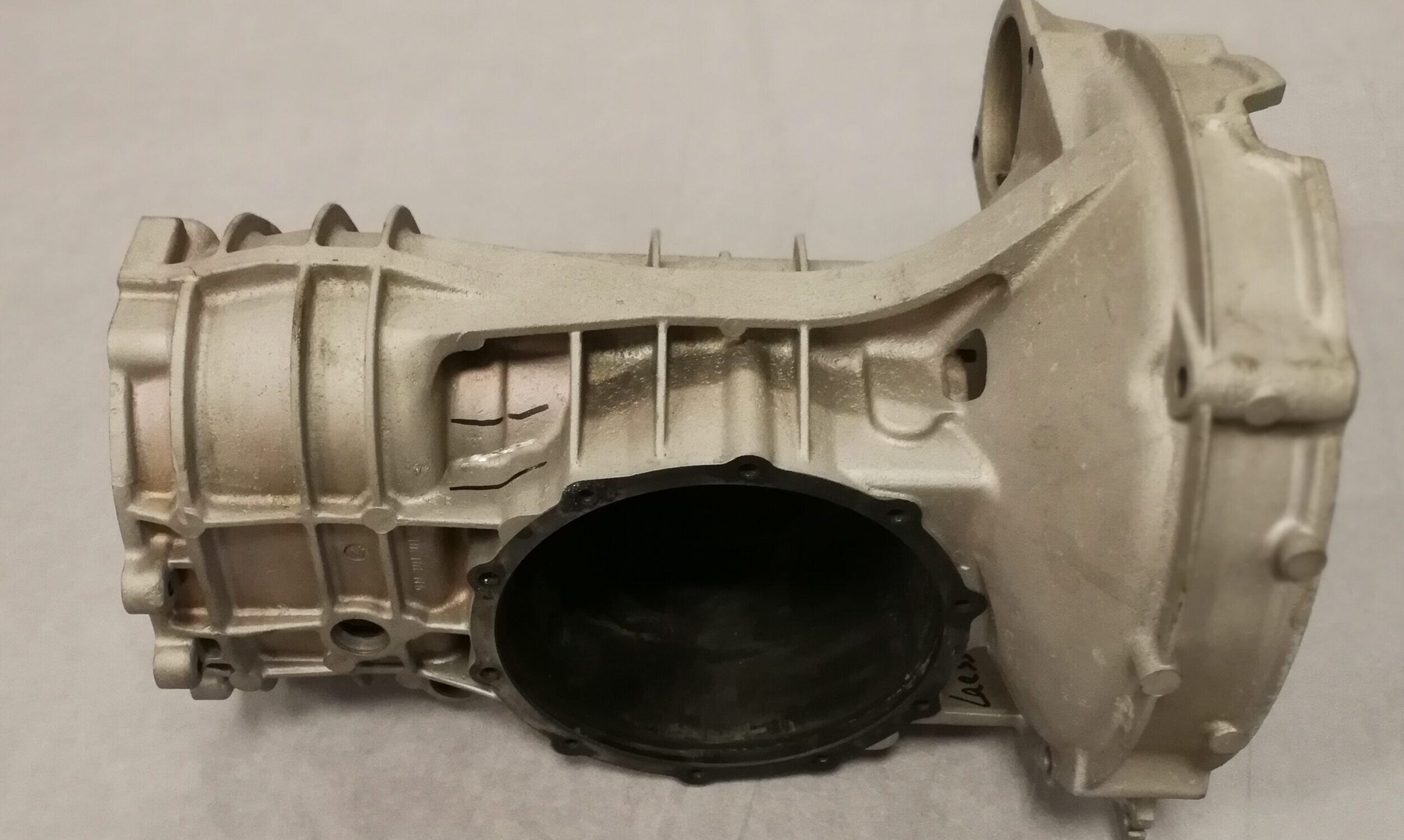

Magnesium welding

We also draw on many years of experience in the field of magnesium welding.

We weld aluminium-magnesium alloys with high strength and also die-cast alloys.

We work exclusively with a pure laser. The fact that magnesium alloys have a low flash point, are easy to ignite and extremely susceptible to cracking makes welding them a special challenge.

There are virtually no tolerances within the welding process, the process window is extremely small.

Examples of work in our classic car workshop:

Vintage mercedes pagoda

Vintage Motorcycle

Vintage mercedes pagoda

Vintage Bentley, 1932

Vintage Porsche

Vintage MG Midget

Vintage Ferrari

Classic car workshop

Classic car repair

Classic car workshop

Vintage Motorcycle

Classic car repair

Vintage Horch, Type 853, 1937

Vintage Rolls Royce, 1927