Vintage car

cylinder head repair

The cause for a necessary cylinder head repair can be a wide variety of faults in your classic car. Either the head gasket no longer completely seals the combustion chamber from the water-bearing part or cracks have formed in the spark plug thread and between the intake and exhaust valves. In addition, the valve seats may be worn or damaged.

In all these cases, there is a loss of compression (reduced power) or – in the worst case – capital engine damage.

At TM Classic Cars we specialise in cylinder head repairs using the latest laser welding techniques. This technique enables us to guarantee a distortion-free repair. The component is cold welded. Distortion of the cylinder head resulting from heating is excluded with this method. The weld seam width is often only between 1 – 0.2 mm wide, which means very precise heat guidance.

Thanks to our many years of experience and the use of coordinated welding filler metals, we are able to repair virtually any cylinder head. No matter whether it is made of aluminium or grey cast iron.

Cylinder head repair

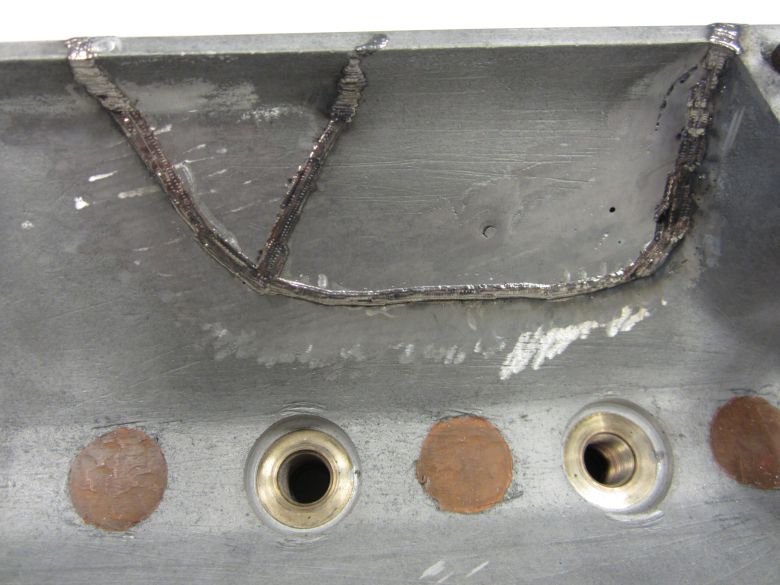

Damage to the water jacket

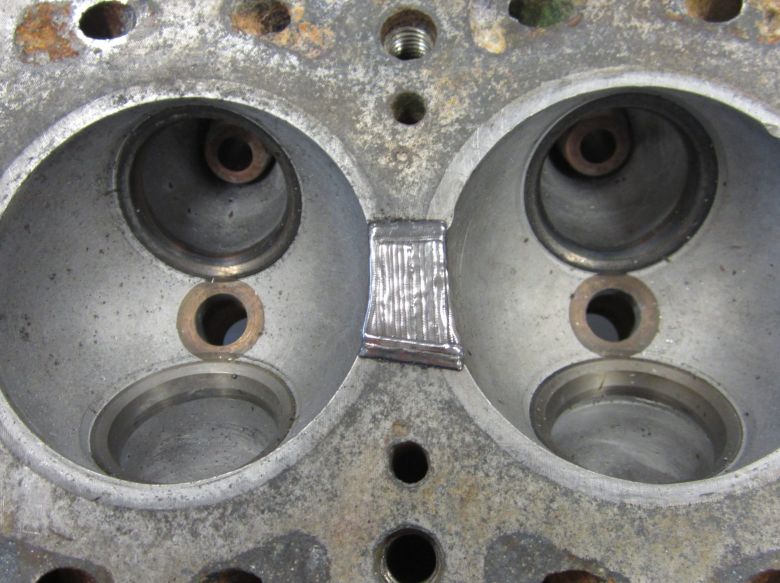

Broken out web between the combustion chambers on the cylinder head

Cracks on the camshaft liner

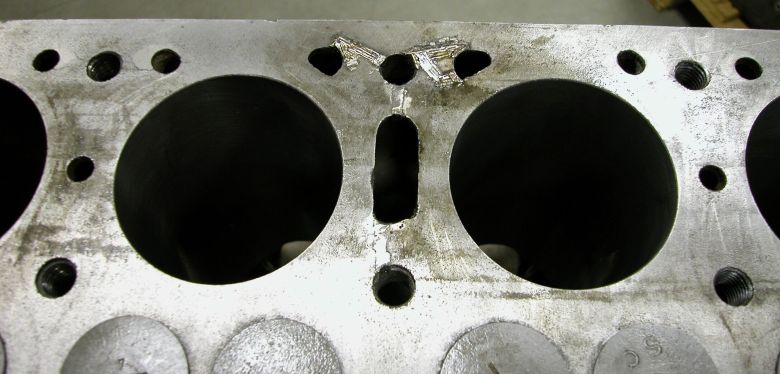

Broken out wall on cylinder head

Fortunately, the broken-off parts of the wall on the cylinder head were still there. They were fitted precisely and welded to the full wall thickness. We metallurgically examined the broken-off web between the combustion chambers in order to locate, remove and grind out all defective areas. Finally, the web was sealed with a special, heat-resistant aluminium alloy. The damages on the water jacket are blowholes that already originate from the manufacturing process of the engine block. We ground them out and generously rebuilt them. The cracks on the camshaft lane were also ground out and rebuilt in full wall thickness.

Vintage Alfa Romeo 8C from the 1930s, racing car at Le Mans

Cylinder head repair

Washouts in the combustion chamber of the cylinder head

We coated the combustion chamber with a special, highly temperature-resistant aluminium alloy. In doing so, we can get as close as 50 µ to the valve seat rings during welding without risking distortion.

The subsequent X-ray inspection of this classic car repair shows that the connection is 100% guaranteed and the additive fuses 100% with the base material.

Vintage Ford GT 40, Mk 1

Washouts have been caused by racing use

This is a type of damage that occurs quite often on highly stressed engines and which we also repair very frequently in modern motorsport and prototype construction.

Cracks in the cylinder around the stud thread

Damage, internal, to the cylinder track

In laser welding, we use a mix of different additional materials to meet the connection to the base material and the subsequent load. Defects are gouged, filled and ground at the appropriate angle. Internal damage to the cylinder bore can also be filled and reground using laser welding. Afterwards, the cylinder only needs to be honed again.

Vintage Horch Type 853, 1937